Services

WHAT WE DO

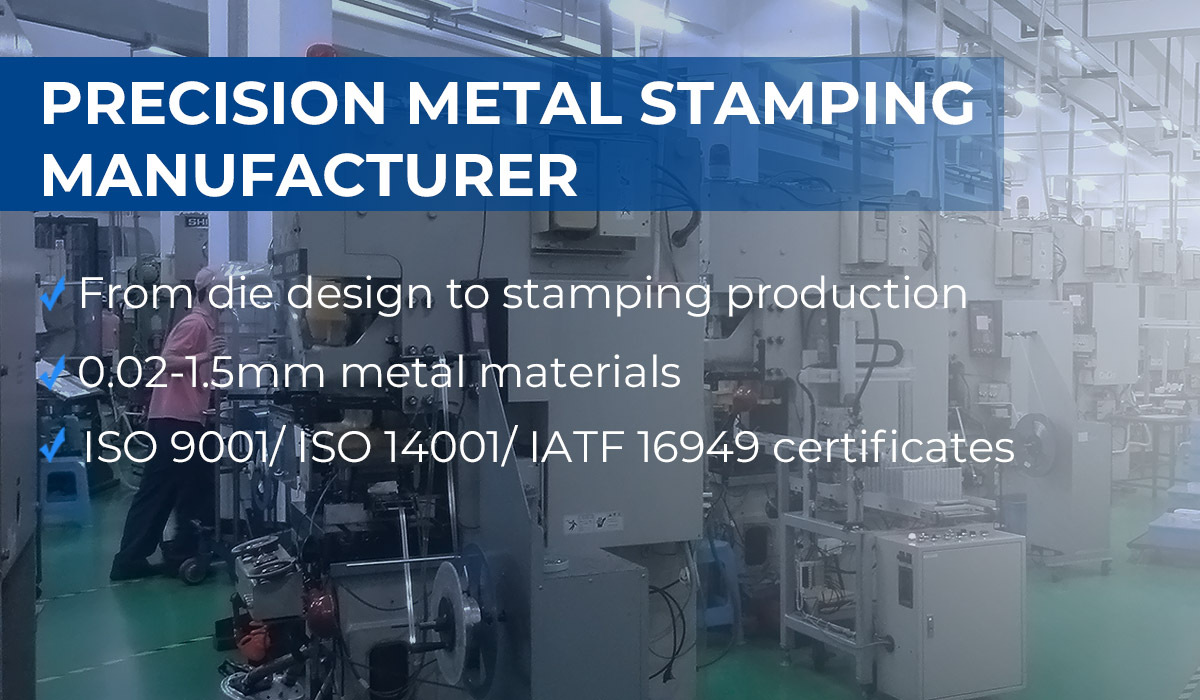

Precision Metal Stamping Solution: Tooling, Prototype, and Production Services for all kinds of metal stamping parts and components. We handle parts that range from 0.02mm to 1.5mm in thickness for industries of medical, automotive, electronics, etc.

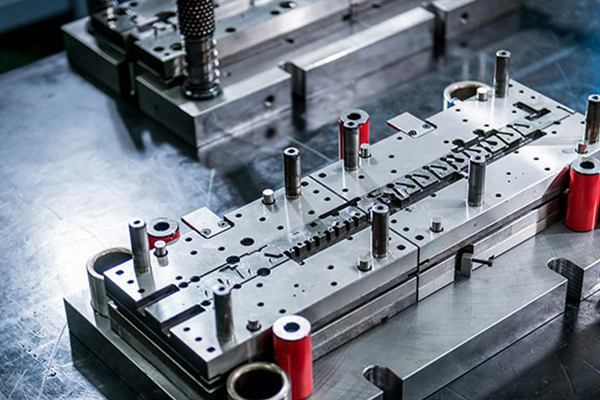

In-House Tooling: we can create completely customizable products in a short amount of time. And the materials, equipment and processes can be adjusted during the production processes.

Rapid Prototyping: test and improve your stamped component design quickly and inexpensively.

Production: as an international company, we deliver cost-effective solutions for high-volume parts and maintain short lead times.

CONTACT US NOW. Send us your requirements and get the best evaluation and solution for free.

WHY CHOOSE US

In-House Tooling and Prototyping: short lead times and premium quality assurance. Adjust your design conveniently.

Competitive Price: with 86 years of experience, we have the capacity to deliver cost-effective solutions for a variety of industries.

On-Time Production: 3 factories in China, Japan, and Vietnam with 43 advanced stamping machines ranging from 10 to 80 tons.

Certification: ISO9001, ISO14001 and IATF16949.

Nondisclosure Agreement: commitment to protect all of your information.

CONTACT US NOW. Send us your requirements and get the best evaluation and solution for free.

WHY CHOOSE US

In-House Tooling and Prototyping: short lead times and premium quality assurance. Adjust your design conveniently.

Competitive Price: with 86 years of experience, we have the capacity to deliver cost-effective solutions for a variety of industries.

On-Time Production: 3 factories in China, Japan, and Vietnam with 43 advanced stamping machines ranging from 10 to 80 tons.

Certification: ISO9001, ISO14001 and IATF16949.

Nondisclosure Agreement: commitment to protect all of your information.

CONTACT US NOW. Send us your requirements and get the best evaluation and solution for free.

Product Cases

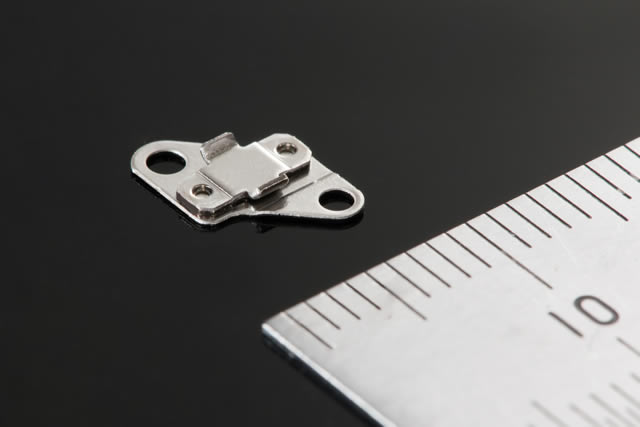

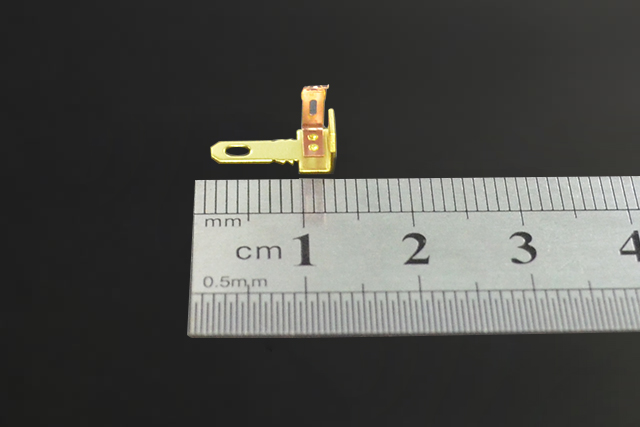

| Product name | Stand |

|---|---|

| Material | SUS304-1/2H SUS304-BA |

| Specification | T0.25/T0.35×6.0×9.0 |

| Characteristic | Riveting strength > 10kg |

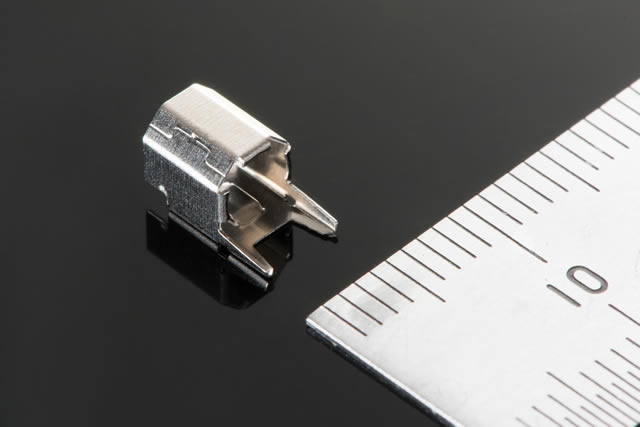

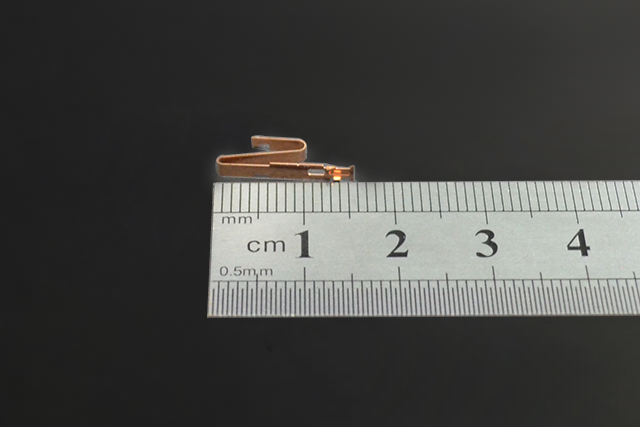

| Product name | Stand |

|---|---|

| Material | SUS301-3/4H |

| Specification | T0.20×9.0×5.0 |

| Characteristic | Bending and riveting |

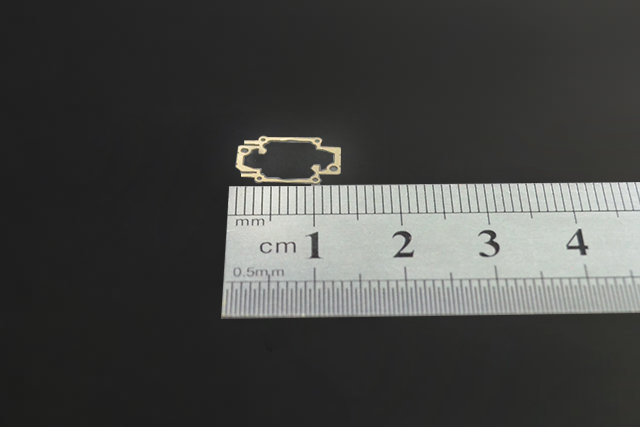

| Product name | Plate shrapnel |

|---|---|

| Material | SUS304 |

| Specification | T0.03 |

| Characteristic | Heat treatment after stamping |

| Product name | Carbon brush |

|---|---|

| Material | Brass %2B beryllium copper |

| Specification | T0.5*13 |

| Characteristic | Riveting Process in dies |

| Product name | Plate shrapnel |

|---|---|

| Material | Beryllium copper |

| Specification | T0.15*15 |

| Characteristic |

| Product name | Plate shrapnel |

|---|---|

| Material | EFTEC-64T |

| Specification | T0.2*17 |

| Characteristic | Battery shrapnel used for shaver |

Service Process

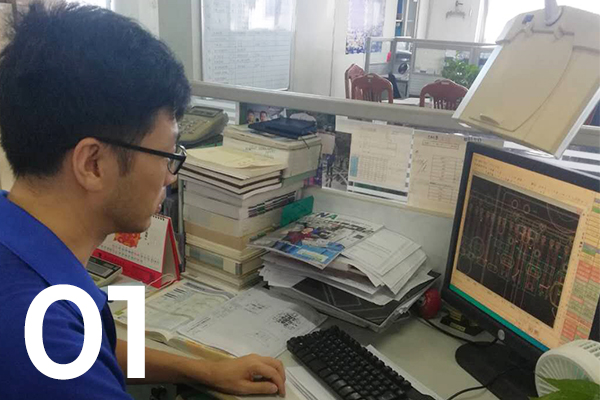

Design

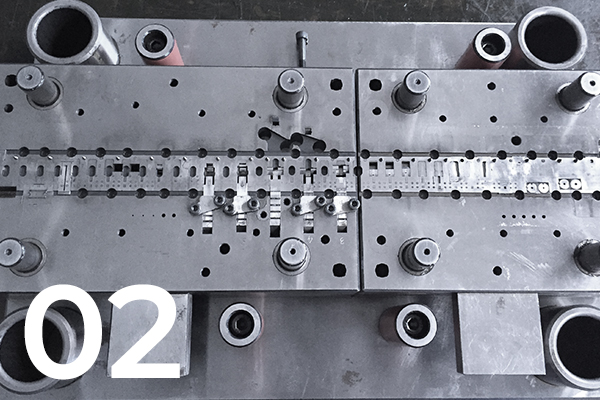

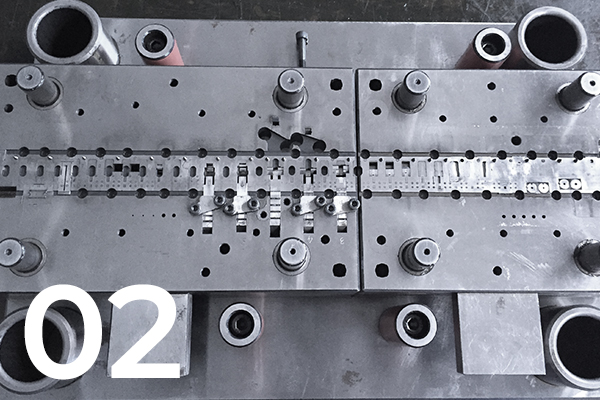

Tooling

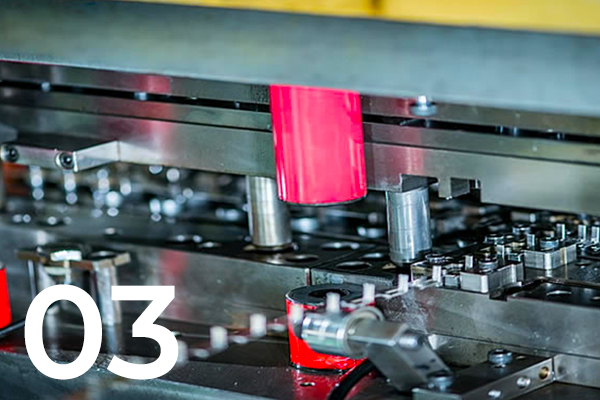

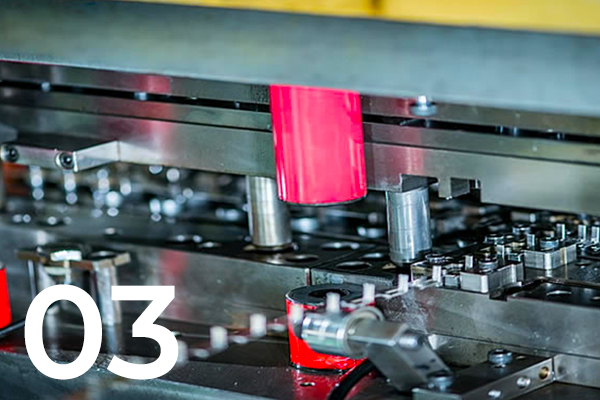

Stamping

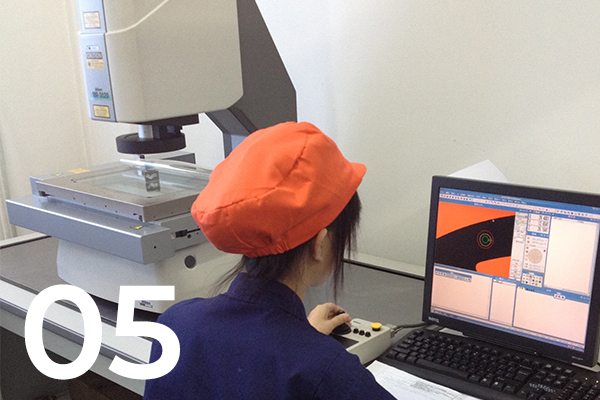

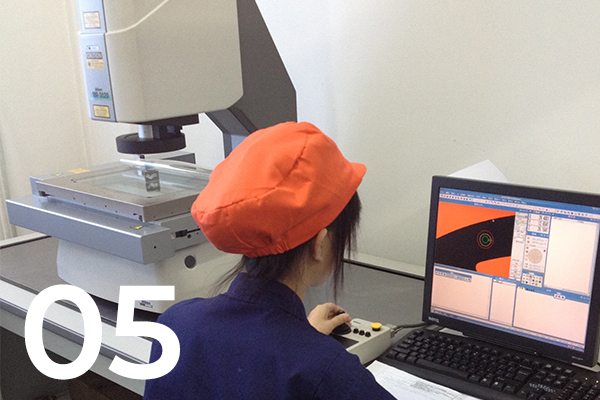

Measuring

Inspection

Packing

Service Process

Design

Tooling

Stamping

Measuring

Inspection

Packing

About Hashimoto

Hashimoto Precision Chinese factory (HSC) was established in December 2002. Head office in Japan, we bought land and built another factory in Hanoi, Vietnam in 2012.

From die design to stamping mass production, these are completed in HSK group to quickly meet customers’ needs. We have obtained ISO 9001, ISO 14001 and IATF 16949 certificates.

We mainly use non-ferrous metal materials, with the thickness of 0.02 mm to 1.5 mm.

The products (such as terminals, brackets, shrapnel, magnetic shells, shielding covers, precision gaskets etc.) are mainly used for consumer electronics, medical, automotive and other fields.

There is a stamping clean room which can make production for camera ND filters and PET shades. The carrier tape packaging can be done in both the clean room and in normal condition. The shrapnel products are heat treated in the group.